In industries where air quality directly determines product reliability, worker safety, and operational efficiency, air filtration is far more than an environmental consideration — it is a critical engineering requirement. From semiconductor fabrication to pharmaceutical production, cleanroom environments rely on advanced filtration systems to control airborne contaminants. At the heart of these systems lies the Industrial HEPA Box, a specialized terminal filtration device that ensures ultra-clean airflow delivery. Among global manufacturers, HEALU stands out for its precision-engineered HEPA box solutions that meet the most demanding cleanroom standards.

1. The Role of Industrial HEPA Boxes in Air Filtration Systems

An Industrial HEPA Box serves as the final filtration stage in cleanroom air supply systems. It is typically installed at the end of ductwork or within ceiling grids, where filtered air enters the controlled environment. Equipped with High-Efficiency Particulate Air (HEPA) filters — capable of capturing 99.97% of particles as small as 0.3 microns — the box ensures that only purified air reaches sensitive production areas.

Unlike ordinary ventilation systems, HEPA boxes are designed for environments requiring particle-free air. This includes semiconductor manufacturing, precision optics, biotechnology laboratories, and medical device assembly lines. The consistent performance of these boxes directly impacts yield rates, contamination levels, and overall process stability.

2. Inside the Structure: Engineering Behind the Clean Air

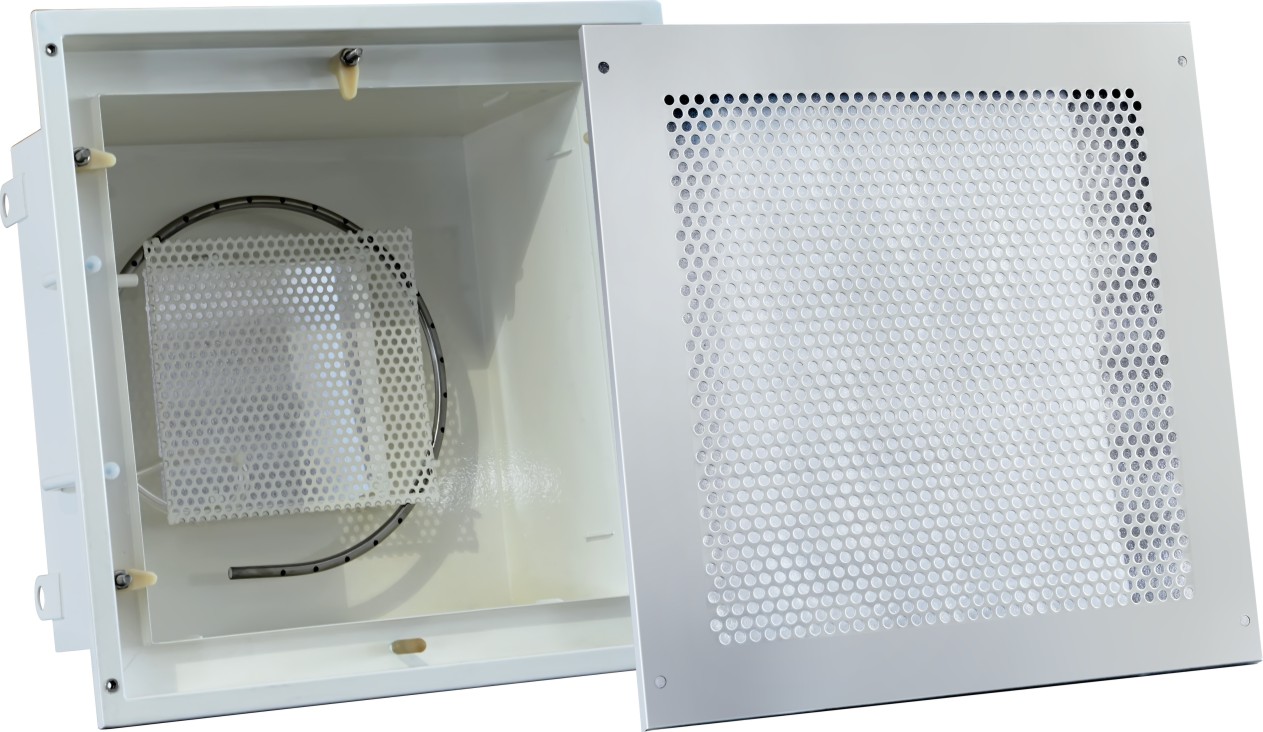

The efficiency of an industrial HEPA box lies in its aerodynamic design and precision filtration integration. A standard HEPA box typically consists of four key components:

Housing Chamber: Made from high-quality galvanized steel or aluminum alloy, ensuring corrosion resistance and structural integrity under constant airflow pressure.

HEPA Filter Module: The filtration core, composed of micro-glass fiber media arranged in a pleated format for maximum surface area.

Air Diffuser Plate: Distributes air evenly across the cleanroom, minimizing turbulence and maintaining laminar flow.

Airflow Regulating Damper: Allows adjustable air volume control to ensure consistent pressure across multiple terminal units.

HEALU’s industrial HEPA boxes feature laser-welded housings, precision gaskets for leak-proof sealing, and customized inlets compatible with various duct configurations. These engineering choices prevent air bypass, reduce pressure loss, and extend filter life — ensuring both energy efficiency and long-term operational reliability.

3. Why Industrial HEPA Boxes Are Critical for Modern Cleanrooms

The modern cleanroom environment is governed by strict international standards such as ISO 14644, GMP (Good Manufacturing Practice), and Federal Standard 209E. To comply with these requirements, filtration systems must deliver consistent particle control and airflow uniformity.

HEPA boxes play several essential roles in achieving this precision:

Terminal Filtration: Acting as the last line of defense before air enters the clean zone, capturing residual particles and microorganisms.

Pressure Regulation: Maintaining positive or negative pressure environments depending on cleanroom class and process type.

Contamination Control: Preventing airborne pollutants, spores, or fibers from entering sensitive production zones.

Noise and Vibration Reduction: Designed with acoustic insulation to maintain quiet operation in laboratory or sterile environments.

HEALU has refined its HEPA box technology to support modular cleanroom construction, where rapid installation and flexibility are crucial. The company’s models are available in multiple configurations — side inlet, top inlet, and low-profile designs — suitable for both new projects and retrofitting existing systems.

4. Technical Innovations from HEALU

HEALU’s approach to industrial air purification emphasizes innovation, precision, and adaptability. Its latest series of industrial HEPA boxes incorporates:

Integrated Pressure Taps: For real-time monitoring of filter pressure drop and performance diagnostics.

Optional ULPA Filters: Providing filtration efficiency up to 99.9995% for ultra-critical applications.

Antibacterial Coating Technology: Prevents microbial growth on the filter frame and housing.

Energy-Efficient Airflow Design: Optimized diffuser plates reduce system resistance, lowering operational power consumption.

Customizable Dimensions and Materials: Stainless steel, aluminum, and powder-coated finishes available to suit diverse industrial environments.

These innovations make HEALU’s HEPA box systems ideal for industries with strict contamination thresholds — from microelectronics and aerospace manufacturing to sterile pharmaceutical packaging.

5. Industrial Applications Across Multiple Sectors

HEPA boxes are indispensable components in several sectors that demand controlled environments. HEALU’s industrial HEPA box solutions are widely deployed in:

Pharmaceutical Cleanrooms: To ensure aseptic processing and packaging conditions.

Semiconductor & Electronics Plants: To protect sensitive wafers and circuit boards from microscopic particles.

Food and Beverage Production: To maintain hygienic air conditions during filling and packaging.

Laboratory & Medical Facilities: To support infection control and biosafety protocols.

Precision Optics Manufacturing: Where dust particles can compromise lens accuracy and product yield.

Each application requires a specific airflow pattern and filter configuration, and HEALU’s engineering team works closely with customers to deliver tailored solutions that exceed compliance standards.

6. HEALU’s Commitment to Quality and Certification

HEALU’s industrial HEPA boxes are tested in accordance with international standards including EN 1822, ISO 29463, and IEST-RP-CC007. Every unit undergoes integrity testing — such as DOP/PAO leak tests — before delivery. The company maintains comprehensive documentation for traceability, ensuring regulatory compliance for customers in GMP-regulated industries.

Moreover, HEALU’s manufacturing facilities implement ISO 9001-certified quality management systems and utilize automated inspection equipment to guarantee precision in every step of production. The result is a reliable product that upholds the purity and safety requirements of advanced industrial environments.

7. Conclusion

In a world where microscopic particles can cause million-dollar losses, precision air filtration is not optional — it’s essential. The Industrial HEPA Box serves as the silent guardian of purity, protecting products, processes, and people alike.

With advanced engineering, stringent quality control, and a commitment to innovation, HEALU provides industrial HEPA box solutions that redefine what clean really means. Whether for pharmaceuticals, electronics, or aerospace manufacturing, HEALU’s filtration systems deliver dependable performance — ensuring every breath of air meets the highest standards of cleanliness.

https://www.healuair.com/how-industrial-hepa-box-redefines-cleanroom-air-filtration-standards.html